In recent years, the automotive industry has undergone a significant transformation to address environmental concerns and reduce harmful emissions. One of the key advancements in this regard is the implementation of Bharat Stage 6 (BS6) emission norms in India. These stringent standards aim to curb pollutants emitted by vehicles, thereby improving air quality and public health. Central to the success of BS6 compliance are after-treatment systems, which play a crucial role in reducing harmful exhaust emissions.

BS6 after-treatment systems are designed to treat exhaust gases before they are released into the atmosphere. These systems employ advanced technologies to minimize the levels of pollutants such as nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC) emitted by vehicles. By effectively neutralizing these harmful substances, after-treatment systems contribute to cleaner air and a healthier environment for all.

One of the key components of BS6 after-treatment systems is the Selective Catalytic Reduction (SCR) technology. SCR utilizes a catalyst, typically consisting of a mixture of urea (AdBlue) and water, to convert NOx emissions into harmless nitrogen and water vapor through a chemical reaction. This process is particularly effective in reducing NOx emissions, which are major contributors to air pollution and respiratory illnesses.

Another important element of BS6 after-treatment systems is the Diesel Particulate Filter (DPF). DPFs capture and trap particulate matter, including soot and ash, from the exhaust stream, preventing it from being released into the air. Over time, the trapped particles are burned off through a process called regeneration, ensuring optimal performance and longevity of the filter.

Additionally, some vehicles may be equipped with Exhaust Gas Recirculation (EGR) systems as part of their after-treatment setup. EGR systems reduce NOx emissions by recirculating a portion of the exhaust gases back into the engine's combustion chamber, where they act as inert gases and lower combustion temperatures, thereby reducing the formation of NOx.

The integration of these advanced after-treatment technologies into BS6-compliant vehicles represents a significant step forward in the fight against air pollution. Not only do they help automakers meet stringent emission standards, but they also contribute to sustainable development and a greener future for generations to come.

However, it's essential to recognize that BS6 after-treatment systems require proper maintenance and periodic servicing to ensure optimal performance. Regular inspection and replenishment of AdBlue fluid, cleaning or replacement of DPFs, and monitoring of EGR functionality are crucial steps in preserving the effectiveness of these systems.

In conclusion, BS6 after-treatment systems are vital components of modern vehicles, playing a pivotal role in reducing harmful emissions and protecting the environment. As we continue to embrace cleaner technologies and sustainable practices, the widespread adoption of BS6 standards represents a significant milestone in our collective efforts towards a cleaner, healthier planet.

Pollution Control Techniques

1. In Engine - EGR (Exhaust Gas Recirculation System) - This system recirculates a portion of exhaust gases back into the engine's combustion chamber to reduce NOx emissions by lowering combustion temperatures.

Pre-Main-Post Fuel Injection Techniques - These techniques involve controlling the timing and amount of fuel injected into the engine cylinders at different stages of the combustion cycle to optimize fuel efficiency and reduce emissions.

CLFC (Closed Loop Fuel Compensation) - This system adjusts fuel delivery based on real-time feedback from oxygen sensors to maintain optimal air-fuel ratios and reduce emissions.

2. After Engine Treatment of Harmful Exhaust Gases.

Components of ATS - After Treatment System (EGP - Exhaust Gas Processor, EGT - Exhaust Gas Treatment)

1. DOC (Diesel Oxidation Catalyst) - To Reduce CO (carbon monoxide) & HC (Hydro Carbon). Catalyzes the conversion of CO and HC emissions into CO2 and H2O through oxidation reactions. It also aids in the oxidation of NO to NO2.

2. DPF (Diesel Particulate Filter) - Captures and stores particulate matter (PM) or soot from the exhaust stream. At First, It Traps the PM/Soot, and when the Exhaust Gas temperature rises (Approx 350 degrees centigrade) it Burns the PM/Soot and converts it to Ash to prevent filter clogging. This process is called DPF Regeneration. Sometimes Thermal Management is required to achieve the Regeneration Temperature.

3. Mixing Chamber - Where DEF (Diesel Exhaust Fluid) / AUS 32 (Aquous Urea Solution - 32.5% Purified Urea & 67.5% Distilled Water) / AdBlue is injected into the exhaust stream.

4. SCR (Selective Catalytic Reduction) - To Reduce The NOx. After Receiving Adequate Temperature (Approx. 210 degrees centigrade and Above) Urea (CH4N2O) Decomposited to Ammonia (NH3) and reacted with NO2. After Reaction Excess NH3 (Ammonia), N2 (Nitrogen Gas) & H2O (Water Vapour) Released.

5. AMOX (Ammonia Oxidation Catalyst)/ASC (Ammonia Slip Catalyst) - Converts excess ammonia (NH3) into harmless nitrogen (N2) and water vapor (H2O).

Sensors Used in ATS - After Treatment System (EGP - Exhaust Gas Processor, EGT - Exhaust Gas Treatment)

1. NOx Sensors - Include upstream and downstream sensors to monitor NOx emissions before and after treatment. (Upstream NOx Sensor - To Determine the NOx Coming From Engine Exhaust, Downstream NOx Sensor - To Determine the Performance of After Treatment System)

2. Temperature Sensors - 3 Nos/4 Nos/5 Nos Depends upon the Models (Positioned at various locations within the after-treatment system to monitor exhaust gas temperatures.)

3. Delta Pressure (DP) Sensor - Measures pressure differentials across the DPF to assess particulate matter (PM) accumulation and determine the need for regeneration.

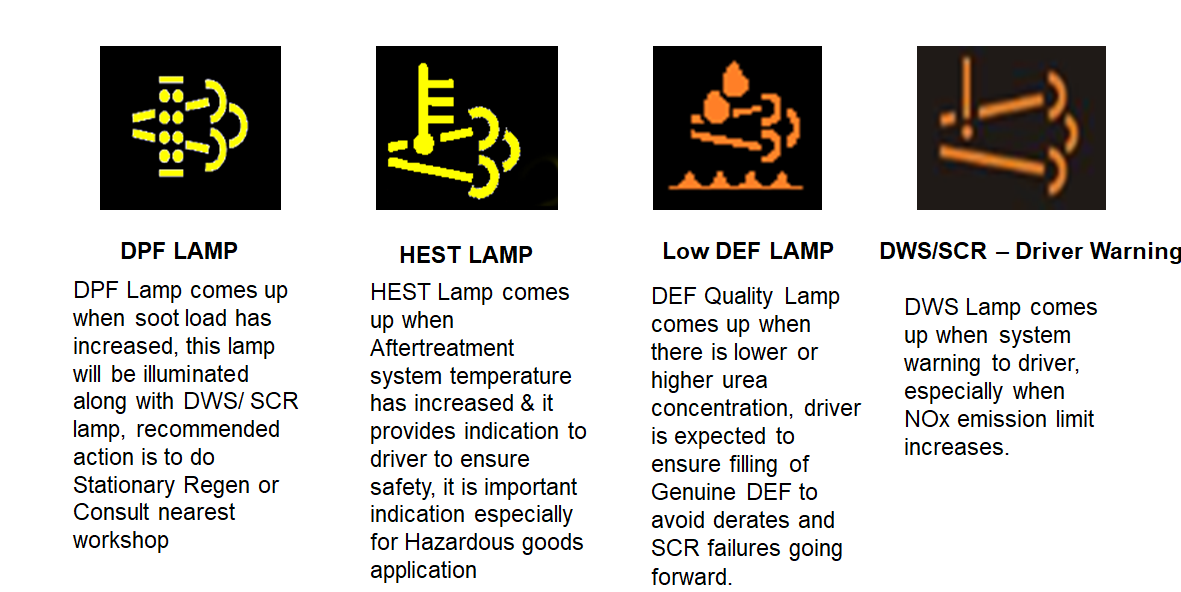

Some Important Symbols Related To After Treatment System (ATS)

Comments